Knife GrinderDesigned for regrinding of our standard cast steel knives in your own workshop. The unit comprises a grinding head with a motor mounted on a traversing carriage running on a cast iron slide base and is supplied complete with a traversing drive electric motor drive and controls.

|

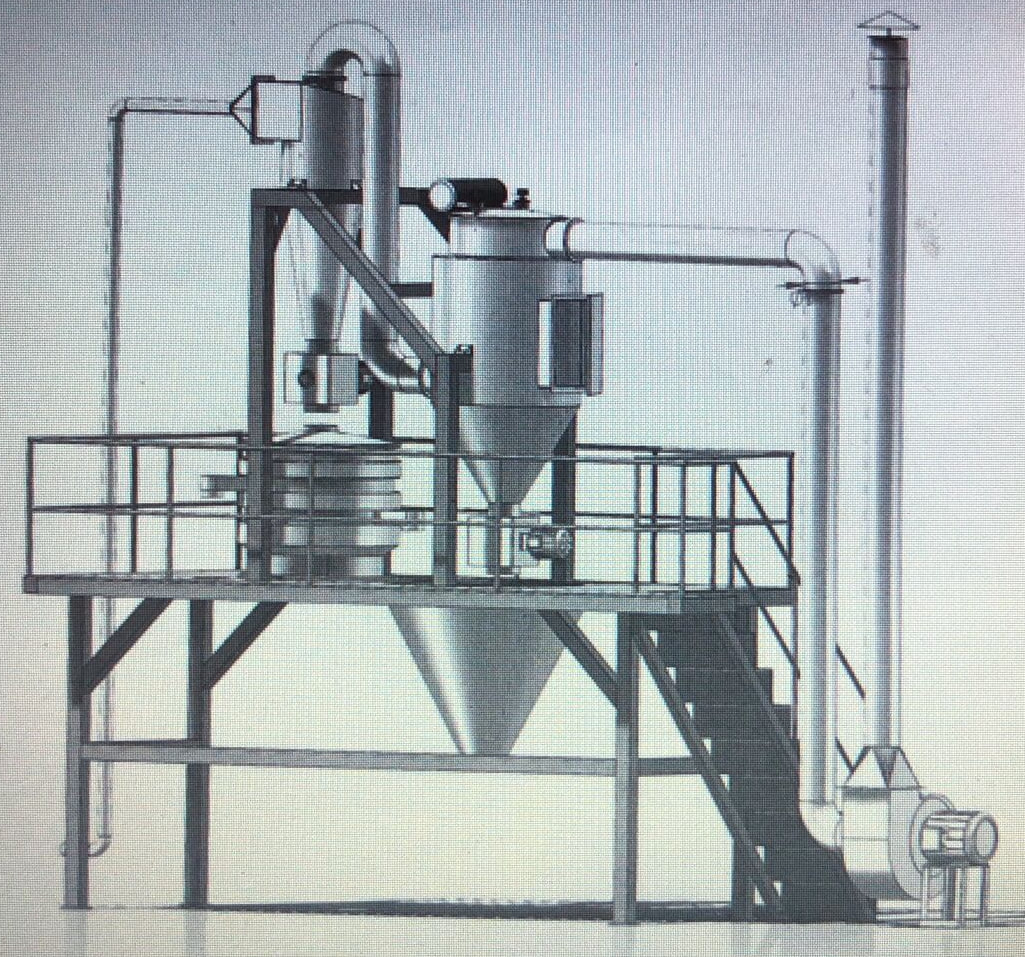

Cyclone Dust CollectorA cyclone dust collector is a type of dust collection system that uses centrifugal force to separate dust particles from the air. It works by creating a vortex inside a cylindrical container, causing heavier particles to be forced to the outer wall and fall into a collection bin, while the clean air is drawn out through the center. This type of dust collector is often used in industrial settings to capture and remove dust and other airborne particles from the air, improving air quality for workers. It is an effective and efficient way to control dust and maintain a clean and safe work environment.

|

PulverizerA pulverizer is a mechanical device used for grinding, crushing, and pulverizing a wide variety of materials. It is commonly used in industries such as agriculture, and manufacturing to reduce the size of solid materials into smaller particles or powders.

Pulverizers typically consist of a rotating drum or cylinder with hammers, blades, or other grinding tools that crush and grind the material against a stationary surface. The size and type of pulverizer can vary depending on the material being processed, and they are often used to prepare materials for further processing or to create a final product. |

High Speed EmulsifierA high-speed emulsifier is a type of industrial equipment used to mix and emulsify slurry or paste materials, typically in the food, pharmaceutical, and cosmetic industries. It is designed to rapidly blend and disperse two or more immiscible slurries or pastes into a stable emulsion. High-speed emulsifiers typically use a rotor-stator system to create intense shear forces, breaking down the droplets and creating a uniform mixture. These machines are capable of achieving high levels of dispersion and emulsification in a short amount of time, making them ideal for large-scale production processes.

|

Quick links |

cHOOSE A LANGUAGE |

FOLLOW US |

coNTACT DETAILS

|